New service: Vulcanized Orings

New service: Vulcanized Orings

Fluoroelastomer, FKM, FPM, Viton®… What a mess just with the name, whose commercial reference has been imposed more than its technical official denomination! That’s why we have decided to write a small didactic guide about this material so common in our markets.

First of all, let’s put some order:

Fluoroelastomer: this is a synthetic rubber based on fluorocarbon compounds containing carbon-fluorine bonds.

FPM: European name DIN/ISO 1629.

FKM: American name ASTM D1418.

Viton®: is a registered trabdemark of Chemours.

Aflas®: is a registered trademark of Asahi.

Fluorel®: is a registered trademark of Dyneon, a division of the 3M Company.

Brief history of the FKM

The compound was developed by DuPont in 1957 and initially focused on aerospace applications. After its introduction, its numerous variants gained mainly in chemical resistance, especially against concentrated bases or aromatic hydrocarbons, the 2 most frequent weak points of the original FKM. In the mid-1970s, Asahi Glass Co. launched a new breakthrough, a blend of polypropylene and FKM, called Aflas®.

Main characteristics

FPM offers an excellent combination of mechanical properties sought in a rubber, such as chemical inertness and thermal resistance.

Varieties

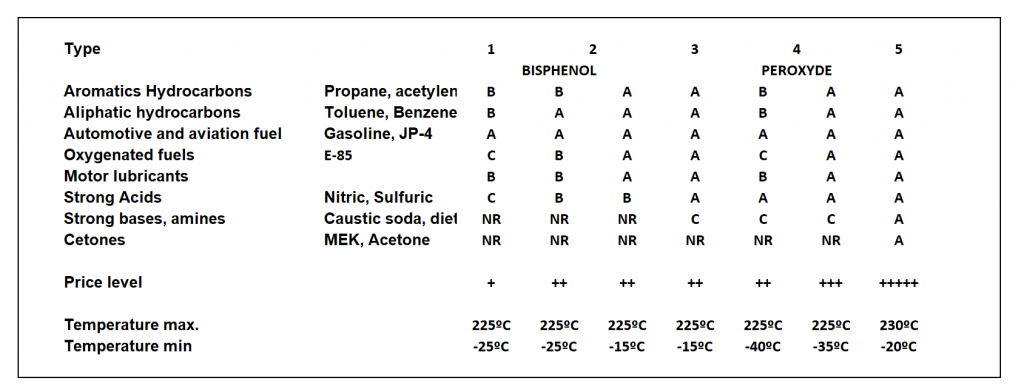

The FKM cited, in most chemical resistance tables (including ours), refers to type 1, cured with Bisphenol, the closest to the original compound. However, peroxide cured polymers are more suitable in alkaline environments or in contact with high temperature water and steam. At the other end of the table, we find Viton Extreme® (ETP) or fluoroelastomer FEPM according to ASTM. It has the particularity of being resistant in highly alkaline solutions, steam and amines, but is relatively unknown in the market, due to its difficult processing.

Variants

The articles manufactured in FKM can be supplied with a wide variety of options or certificates: lubrication, PTFE coating, conductive, AED, USP, 3A, FDA, CE1935/2004, KTW, NSF, detectable material and in all colours (the most common being brown and black).

New service: Vulcanized Orings

New service: Vulcanized Orings