Interactive chemical resistance table

MATERIALS

Common gaskets are made from elastomers For two reasons:

- They are easy to install and can be deformed at your convenience.

- They are mounted in housings and adapt to them by expansion or by upsetting.

Elastomers are classified into thermosets and thermoplastics. They differ in the degree of crosslinking after the curing or vulcanization reaction and in their behavior with temperature. The elastomers of greatest interest from the point of view of tightness are thermosetting.

THERMO-STABLE ELASTOMETER POLYMERS

The main characteristic of a thermoset elastomer is that when heated it cannot be molded due to the high chain crosslinking.

In particular, the family of rubbers has certain properties of great industrial interest:

- They can be electrical insulators, conductors or antistatic.

- Resistant to a greater or lesser extent to the elements and solar radiation.

- Acoustic and vibration isolators.

- They offer a wide range of service temperatures: -65 ºC to +320 ºC.

- Fire resistant with various behaviors such as flame coloring, smoke, smoldering or self-extinguishing depending on the formulation of the material.

- They admit a great variety of pigmentations.

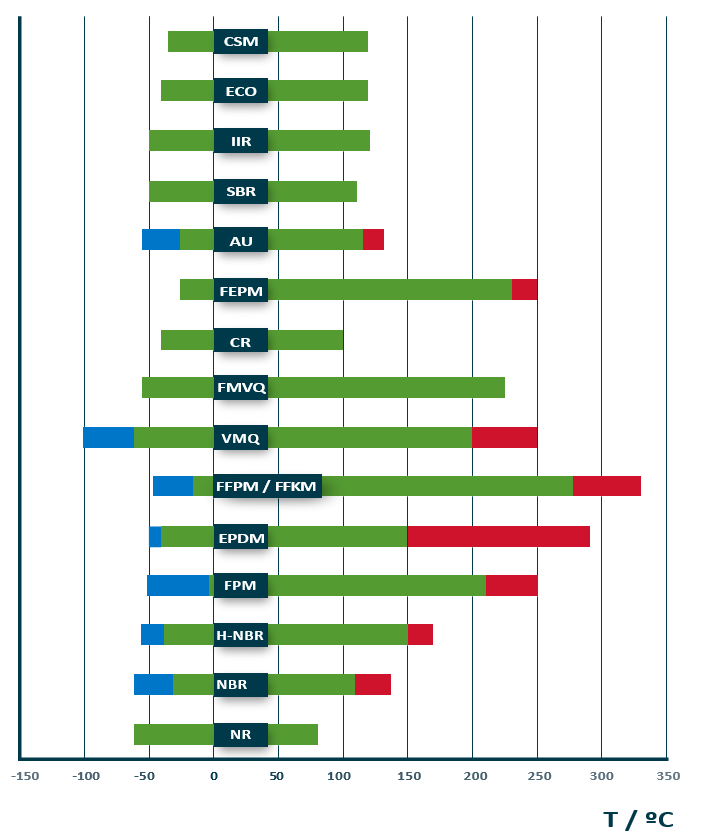

THERMAL RESISTANCE OF THE ELASTOMERS EXPOSED ABOVE:

- Usual range

- Special formulation for low temperature

- Special formulation for high temperature

Caoutchouc perfluorocarboné

They are fully fluorinated polymers with elastomer characteristics and highly recommended for applications with aggressive chemicals at high temperatures.

CHARACTERISTICS OF INDUSTRIAL INTEREST:

- Nearly universal chemical inertness, similar to PTFE. Thermal stability at high temperature.

- Excellent resistance to steam, ozone and weathering.

- When compared to other materials, its price is high.

- They have poor physical properties and limited use in low-temperature services. Attack by fluorinated refrigerants R11,12, 13, 113, 114 ...)

Operating temperature:

-15 ºC to +276 ºC

Special formulation:

-46 ºC to +250ºC

-15 ºC to +327ºC

Tetrafluoroethylene propylene copolymer (FEPM)

Material with high chemical inertness in aggressive media, also known as Aflas ™.

CHARACTERISTICS OF INDUSTRIAL INTEREST:

- Excellent thermal resistance. Good resistance to ozone and weathering.

- Chemical resistance to petroleum derivatives, steam up to +170 ºC, amines, organo-phosphates, strong acids and bases.

- Improved chemical resistance to a wide range of automotive fluids (lubricants, brake fluids), mineral oils, and silicone oils.

- Incompatible with gasoline, ketones, ethers and solvents.

Operating temperature:

-5 ºC to +230 ºC

Special formulation:

-25 ºC to +250 ºC

Fluorocarbon rubber (FPM / FKM)

Fluorelastomers, Viton® being the best known of them, are the most suitable rubbers for continuous service in a temperature range between 200 ° C and 250 ° C and they are also not flammable.

CHARACTERISTICS OF INDUSTRIAL INTEREST:

- Good resistance to hydrocarbons, mineral oils and fats with additives, fuels and both aliphatic and aromatic hydrocarbons, inorganic acids and bases even at high concentrations Good resistance to hydrocarbons, mineral oils and fats with additives, fuels and both aliphatic and aromatic hydrocarbons, acids inorganics and bases even at high concentration.

- In peroxide cured formulations, FPM improves its compatibility with traditionally incompatible fluids such as alcohols, hot water, steam, and alcohol-containing fuels.

- Resistance to ozone and aging.

- Strong swelling in organophosphates (Pydraul 10E), ammonia, amines, saturated steam, superheated steam, polar solvents (ketones, dioxane, ethyl acetate) as well as in highly flammable fluids (Skydrol) and etherglycol-based brake fluids.

- Its benefits suffer strongly for temperatures below -10 ºC.

Operating temperature:

-20 ºC to +210 ºC

Special formulation:

-51 ºC to +225 ºC

-15 ºC to +250 ºC

Hydrogenated Acrylonitrile / Butadiene Copolymer (H-NBR)

Its properties depend on the initial acrylonitrile concentration and the degree of hydrogenation of the butadiene copolymer.

CHARACTERISTICS OF INDUSTRIAL INTEREST:

- Regarding NBR, its chemical inertness, its resistance to temperature as well as its resistance to traction and tearing, its elongation and its resistance to abrasion are improved.

- Excellent resistance to oil, steam, hot water and ozone.

- The curing reaction can be with sulfur or with an organic peroxide, depending on the properties to be enhanced.

- Attack by polar organic solvents (ketones), esters, aromatics and strong acids.

- Poor flame resistance and poor electrical properties.

Operating temperature:

-36 ºC to +150 ºC

Special formulation:

-55 ºC to +160 ºC

Fluorine Vinyl Methyl Silicone Rubber (FVMQ)

Fluoro silicone rubbers improve the chemical inertness of silicone but are more expensive.

CHARACTERISTICS OF INDUSTRIAL INTEREST:

- Improves the chemical resistance of silicone rubber (VMQ) to aromatic hydrocarbons, chlorinated organo and petroleum derivatives.

- Excellent resistance to ozone, aging and low temperatures.

- Buenas propiedades eléctricas.

- Poor wear resistance. Gas permeability similar to VMQ.

- Attack by acids and bases, silicone oils and greases, steam and low molecular weight organochlorines.

Operating temperature:

-55 ºC to +225 ºC

Ethylene / Propylene / Diene Terpolymer (EPDM)

Elastomer with good resistance to wear.

Its composition contains between 45% and 75% of ethylene, being generally more resistant the higher this percentage is.

CHARACTERISTICS OF INDUSTRIAL INTEREST:

- Good resistance to hot water, steam, bleaches, oxidizing media, acids, bases, polar solvents, ketones, hardly flammable liquids of the HFC group, some types of the HFD group and etherglycol-based brake fluids.

- Good resistance to ozone, weathering and low temperature.

- The curing reaction can be with sulfur or an organic peroxide, depending on the properties to be enhanced.

- Good electrical insulator.

- Strong swelling in mineral oils and fats, aromatic and chlorinated hydrocarbons.

Operating temperature:

-39 ºC to +150 ºC

Special formulation:

-50 ºC to +288 ºC

Acrylonitrile / Butadiene Copolymer (NBR)

Synthetic rubber developed from a copolymer of acrylonitrile and butadiene, whose acrylonitrile concentration is variable between 18% - 50%.

If the concentration of acrylonitrile is low, the NBR obtained has a higher resistance and its elasticity at low temperature is improved. If the acrylonitrile concentration is high then the chemical resistance to oil increases, however the elasticity and resistance to residual deformation decrease.

CHARACTERISTICS OF INDUSTRIAL INTEREST:

- Good chemical resistance to aliphatic hydrocarbons, mineral oils (highly flammable lubricating oils and hydraulic oils such as HFA, HFB and HFC’s), greases based on mineral oil, animal and vegetable fats, water up to 100 ºC, inorganic acids and bases in low concentration.

- Medium resistance to swelling in fuels with high aromatic content.

- Strong swelling in aromatic hydrocarbons, chlorinated hydrocarbons, highly flammable hydraulic fluids such as HFD, esters, polar solvents (acetone), strong acids as well as ether-glycol-based brake fluids.

- Ozone attack and weathering.

Operating temperature:

-30 ºC hasta +110 ºC

Special formulation:

-60 ºC to +135 ºC

Vinyl Methyl Silicone Rubber (VMQ)

Silicone rubbers stand out for their high thermal resistance and good cold flexibility.

They are highly recommended for high and low temperature applications.

CHARACTERISTICS OF INDUSTRIAL INTEREST:

- Very good resistance to oxygen and ozone.

- The electrical properties are excellent as well as its resistance to the elements.

- Good resistance to vegetable oils, high aniline index oils, motor and gear oils.

- Moderate resistance to swelling in mineral oils and greases, ether-glycol-based brake fluids and water up to 100 ° C.

- Strong swelling in low molecular weight esters and ethers, aromatic and aliphatic hydrocarbons, concentrated acids and bases, and superheated steam.

- The permeability to gases at room temperature is higher than that of other elastomers.

Operating temperature:

-60 ºC to +250 ºC

Special formulation:

-100 ºC to +250 ºC

Chloroprene rubber (CR)

Chloroprene rubber, also known as Neoprene®, was one of the first synthetic rubbers developed to be oil resistant.

It is a general purpose rubber with an excellent balance of physical and chemical properties.

CHARACTERISTICS OF INDUSTRIAL INTEREST:

- Good resistance to ozone and weathering. Offers excellent metal rubber bonds.

- Its resistance to flame is excellent, being one of the few rubbers that is self-extinguishing.

- Good resistance to high aniline point mineral oils, silicone oils and greases, alcohols, glycols, ammonia and refrigerants.

- Strong swelling in aromatic and aliphatic hydrocarbons, ketones, concentrated acids and bases, and steam. It tends to absorb water.

- Low permeability to gases and its electrical properties are poor.

Operating temperature:

-40 ºC to +100 ºC.

Styrene / Butadiene Copolymer (SBR)

This rubber can be a point substitute for natural rubber (NR). Its physical strength, resilience and low temperature properties are generally inferior to those of NR although the heat aging and abrasion resistance properties are better.

Its main application is the manufacture of tires that consumes almost a third of world production.

CHARACTERISTICS OF INDUSTRIAL INTEREST:

- Good resistance to aging and temperature up to 110 ºC.

- Good chemical resistance to acids, lyes, alcohols, glycols and water.

- Low chemical resistance to oxidizing media, mineral acids, greases and lubricants.

- Strong swelling in mineral oils, petroleum-based greases, fuels and aliphatic, aromatic and chlorinated hydrocarbons.

Operating temperature:

-50 ºC to +110 ºC

NOTE: The information shown in this table is only to be used as a reference guide. The tests have been carried out in the laboratory and do not have to reproduce the real field conditions. The User is responsible for the final check of the chemical compatibility of the process fluid with the elastomer of interest. For more information, consult our Technical Department.