New service: Vulcanized Orings

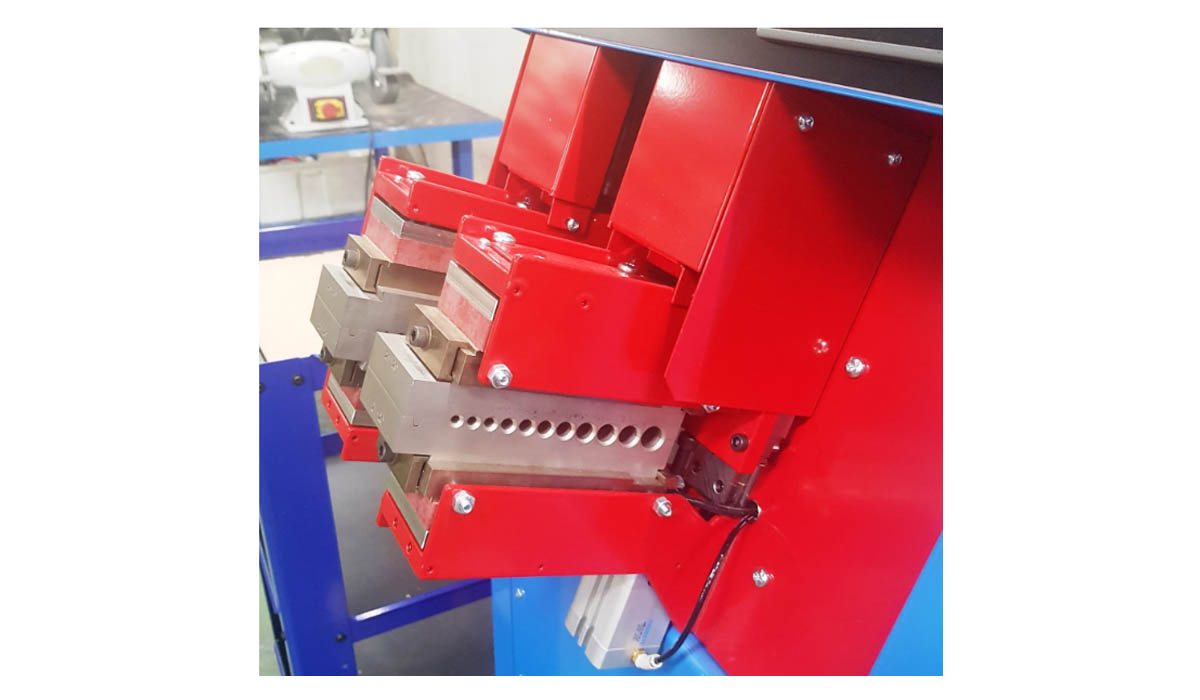

At Epidor Seals and Rubber Technology, we have integrated a new press in our factory, exclusively dedicated to the local vulcanisation of profiles. This new machine allows us to join O-rings in order to manufacture large or non-standard O-rings, without any mould cost and in record time.

It is the ideal solution when you are looking for any large diameter Oring urgently and at an affordable price.

The process

The raw material consists of 2 elements: the cord ring on one side, cut to size according to the desired final inner diameter, and sheets of fresh uncured material on the other. The process, which is semi-automatic, consists of presenting and pressing the ends to the sheet, and then vulcanising this material at high temperatures, creating a strong bond between the ends of the cord. The finishing is done by means of a band polishing machine, in the area of the union.

The quality obtained with this process is within the parameters set out in our O-ring catalogue. Tensile strength tests in an official laboratory according to ASTM gave positive and consistent results.

For the moment, we have focused on manufacturing seals with a section of 3 – 3.53 – 4 – 5 – 5.33 – 6 – 6.99 – 7 – 8 – 9 – 10 – 12 mm, with a minimum internal diameter of 200 mm, and no limit on the maximum…Materials: NBR and EPDM, and soon FKM.

FAQ

What applications can I use this product for?

In static applications, they can be used for any type of application, even in rectangular covers if the housing is designed properly. If in doubt, call our technicians. However, we do not recommend the product for dynamic applications, in which there is a moving part in contact with the seal, and also not in a vacuum, due to the tolerances of the polished area.

Can only O-rings be vulcanised, and with these sections?

We have the moulds prepared for the sections previously indicated. If a project needs another mould, it will have an initial cost of tooling. Profiles of any section can be vulcanised, as long as they are within the maximum dimensions of the press (140 mm x 140 mm)

What is the difference between a “vulcanised” and a “glued” seal?

Orings glued with cyanoacrylate adhesive are a good solution to a problem that requires an immediate solution. We have versatile kits in the form of a case for manufacturing seals on site. However, they do not necessarily withstand aggressive temperatures and pressures and may break on contact with certain chemicals.

On the other hand, vulcanised seals use the same material as the raw material of the cord, without any chemical agent that could alter the characteristics of the seal. In addition, they usually have a better surface finish.

Leave a Reply

Want to join the discussion?Feel free to contribute!