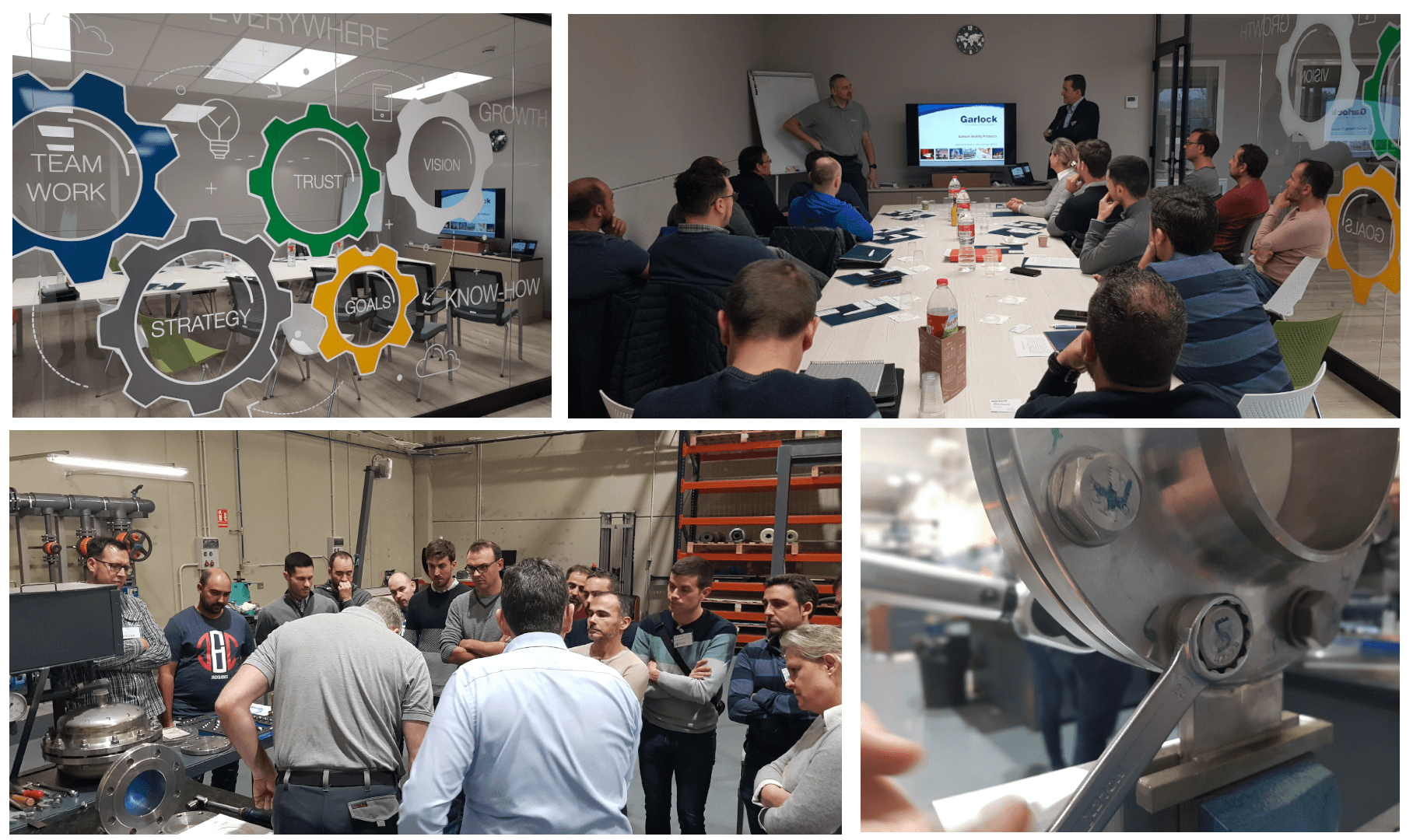

Awareness training of installers EN 1591-4

In the middle of this month of February, Epidor Seals and Rubber Technology organized, with great success, a training session on the assembly and disassembly of flanged joints in critical services, based on the EN 1591-4 standard. For this, they had the support of Epidor Technical Distribution and the manufacturer of materials for flat gaskets, Garlock.

The EN 1591 standard has 4 sections:

- Calculation of tightening torques (EN 1591-1).

- Description of the parameters of a gasket (EN 1591-2).

- Calculation method for metal-to-metal contact type flanged joints (EN 1591-3).

- And the last section refers to the training of the personnel in charge of the assembly of bolted joints, in pressurized systems of critical services (EN 1591-4).

The training took place at the group’s production center in Reus, and was attended by important chemical companies from the Tarragona Chemical Complex. The seminar had a first theoretical part and a second part with practical exercises on assembly / disassembly of gaskets in flanged joints. All attendees participated in the various jobs during the two hours of the practical session.

In Germany and Scandinavia, EN 1591 has the status of law and is mandatory. Its application has highlighted the enormous importance of proactive maintenance over reactive maintenance.

The implementation of EN 1591 in the process industry is done with a proactive maintenance model that provides greater reliability and efficiency of the installation, therefore, an increase in production and profitability of the plant. All this thanks to the direct impact on the reduction of fugitive emissions, a particularly sensitive issue for any plant.

Promoting compliance with EN 1591 is an objective of the action plan developed by Epidor SRT in its commitment to the 2030 agenda and the Sustainable Development Goals.