Seals for hydraulics and pneumatics

Seals for hydraulics and pneumatics form the sealing solution for hydraulic and pneumatic cylinders.

The main function of these components is to prevent leakage of the power transmission fluid in single-acting, telescopic or double-acting cylinders, among others.

In our blog post we explain more about our gasket fabrication service and how a sealing system is configured.

We manufacture seals for hydraulics and pneumatics

More and more customers require customized sealing solutions. To this end, it is crucial to have the capability to manufacture seals in a wide variety of profiles and materials.

Seals for hydraulics and pneumatics are manufactured on CNC lathes. At Epidor Seals and Rubber Technology we have lathes that are equipped with bar loading devices for high volume runs.

We manufacture and supply small and medium series of seals for hydraulics and pneumatics without mold cost.

We also produce short series for prototypes in less than 48 hours. These services will be very useful for you if:

- • You are having trouble locating seals for hydraulics and pneumatics because they are discontinued.

- • They require a minimum quantity of sealing gaskets to be manufactured far in excess of your needs.

The most demanded materials are:

-

- • Elastomers (NBR, EPDM and FPM).

- • Polyurethanes.

- • PTFE with fillers (fiberglass, bronze, graphite, ekonol, PEEK etc…).

Optionally, dimensional analysis of customer-relevant dimensions such as part outside diameter, part height and inside diameters can be performed.

In the catalog “Machined Seals – Customized Sealing” you will find the current models that make up the manufacturing program of seals for hydraulics and pneumatics, as well as information on the materials available for the machining of parts.

In addition, we are able to produce seals for hydraulics and pneumatics in 60 different materials, which are then thoroughly tested in our own laboratory.

On numerical control lathes we manufacture all kinds of seals for hydraulics and pneumatics for the sealing of hydraulic and pneumatic cylinders: scrapers, collars, low friction seals, compact seals, guides, support rings, etc…

Sealing system configuration

Each of the hydraulic and pneumatic seals will have its own importance in the sealing of the hydraulic or pneumatic cylinder of interest. And they can even be combined with each other in what we call the configuration of the sealing system, of which we distinguish 3 groups of parts:

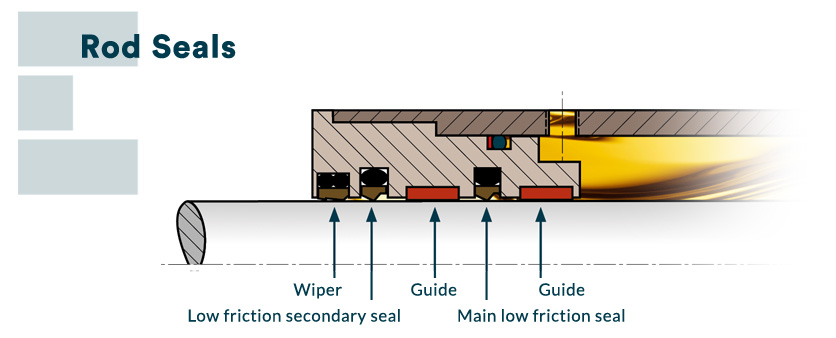

- • Rod seals, including wiper, collars, guides and low friction seals.

- • Piston seals also consisting of collars, guides, low friction seals and compact seals.

- • Static seals: these are parts which, as their name indicates, refer to the static sealing of the various mechanical components of the cylinder. O-rings, X-rings and support rings belong to this group.

Rod seals

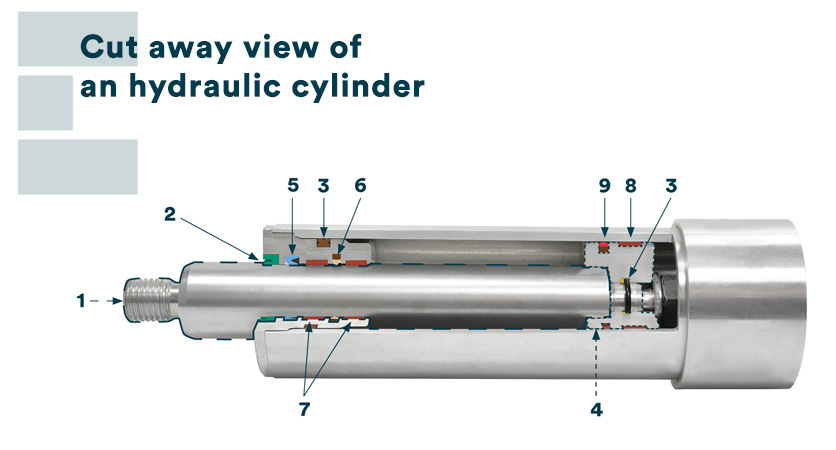

The first part to be discussed is the wiper (2). Its main function is to prevent any dirt that may have been deposited on the surface of the piston rod from entering the cylinder.

We refer to the dust or moisture in the environment of the hydraulic or pneumatic cylinder. This part is located on the outermost part of the cylinder, as shown in the picture above.

Next, there is a U-cup rod seal (5) and a low friction seal (6). Depending on the working conditions, the design of the parts can be modified and combine, for example, two low friction seals instead of a U-cup and a low friction seal as shown in the picture below:

The guides (7) play a key role in preventing metal-to-metal contact when the U-cup and low-friction seals are worn.

If guides were not installed, there would come a time when the rod would no longer be able to move due to seizure or contact of the metal rod with the metal cylinder head.

Piston seals

Like the rod, the main seal that provides sealing between the piston and the cylinder liner is either a U-cup collar or a low-friction seal (9).

The piston also has guides that perform the same function as on the rod, in addition to the correct alignment of the moving assembly (8).

And there are even pistons that combine the guide and seal in the same part, in what we call a compact part, for example, the part called DK 109.

The white parts act as guides, while the blue part is the sealing ring.

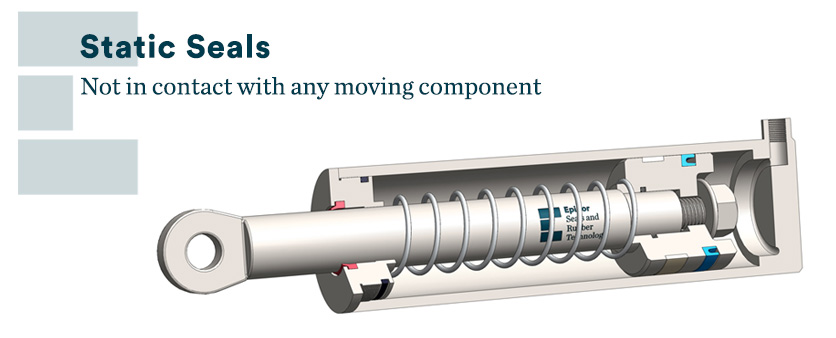

Static seals

They provide sealing between the cylinder head and the cylinder liner, or between the end of the piston rod and the threaded piston.

They are parts that are not exposed to the movement of the surface against which they seal. Among the static seals, the most common are O-rings, X-ring seals and rectangular section seals.

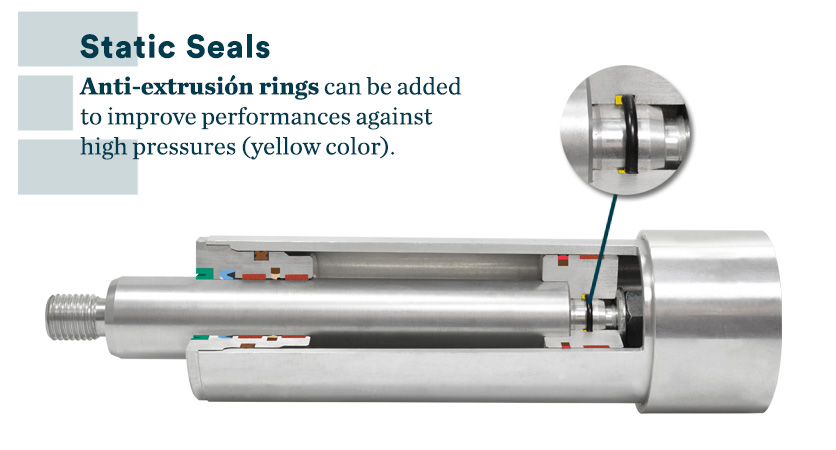

We also have parts known as “support rings” which are added to the static seals to prevent extrusion damage when they are subjected to high pressures (> 250 bar). In the following view of the O-ring installed between the piston and the piston rod, a yellow part can be seen, which is the support ring (3).

For more information, you can consult our website or contact our Technical Department for advice on your application.

Leave a Reply

Want to join the discussion?Feel free to contribute!