New Air CPA piston seal and Air CPA Slim version

At Epidor Seals and Rubber Technology we have developed the new Air CPA piston seal and its variant Air CPA Slim. This piston is equipped with a low friction seal and different features that make it a quick and easy solution to assemble.

In this blog article, we present the new Air CPA and Air CPA Slim machined piston seals. In both cases, the working conditions are for typical pneumatic pressures up to 10 bar; speeds up to 1 m/s and for dry and lubricated air service.

Stay tuned and read on to find out more about the advantages of machined sealing parts and seals and this new product with significant attributes.

Index

Advantages of customized production

As you know, at Epidor Seals and Rubber Technology we specialize in the machined sealing parts and seals. This service offers a number of benefits over standard solutions. Here are some of its advantages:

- • Manufacture of intermediate sizes that are out of the catalogue.

- • Manufacture of quantities according to requirements (short series).

- • Access to more than 50 materials including elastomers, polyurethanes, filled PTFE’s and technical plastics.

- • Shorter delivery times.

- • Possibility of testing prototypes on the Epidor Seals and Rubber Technology pneumatic testing bench.

More than 55 years of experience endorse us as a reference in our customized sealing service, allowing our customers to collaborate with our engineering department in the design of the most suitable seal or part for each application.

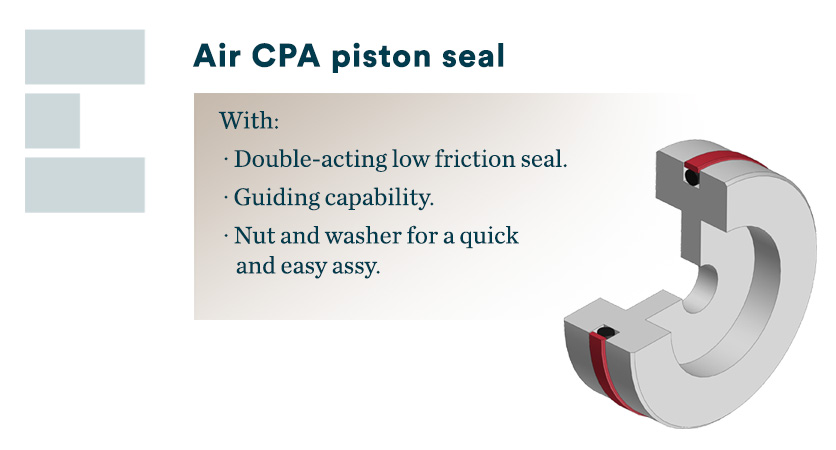

Air CPA piston seal

The new Air CPA piston seal has been designed taking into account a number of factors to get an easier assembly. This piston seal is equipped with a double-acting low-friction seal and guiding capability, with a nut and washer for quick and easy assembly.

The initial size range comprises Ø25 up to Ø100 cylinders, although our engineers in the Epidor Seals and Rubber Technology Technical Department may develop other diameters on request to meet the requirements of any application.

Another highlight of this piston is the materials used in its machining. The bodies are machined from polyacetal resin (POM) or polyamide (PA), both of which are wear-resistant and offer greater performance and durability.

We can also machine the seal in low hardness (90 Sh A) HPU Soft polyurethane or filled PTFE compounds. We have also considered FDA-certified materials for the piston body, friction ring and O-ring. In the following picture you may see our own design:

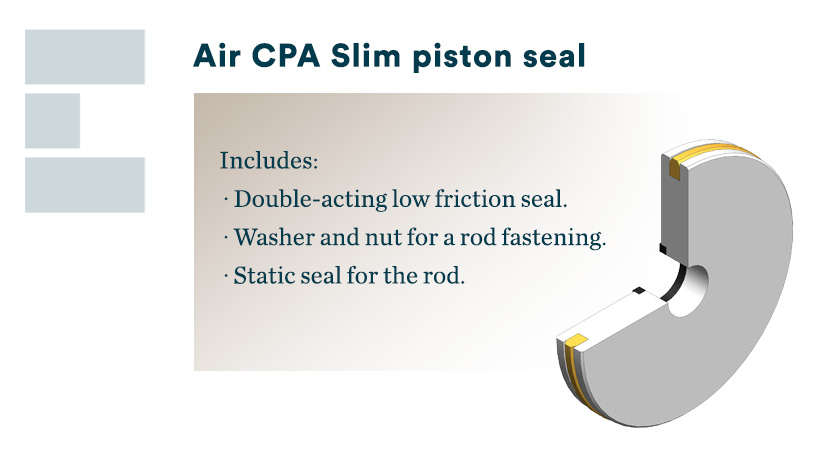

Air CPA Slim piston seal

The Air CPA Slim piston seal is the “thin” version of the Air CPA piston seal designed for those applications in which the groove is reduced or with small space.

The Air CPA Slim piston seal is machined from a thermoplastic compound and incorporates a double-acting seal. The piston is fixed to the rod of the pneumatic cylinder with a washer and nut. It also has a static seal for the rod.

It has the same material configuration as the Air CPA piston and its available range covers cylinders from Ø16 to Ø100, although any diameter can be developed on request. An image of the design is shown below:

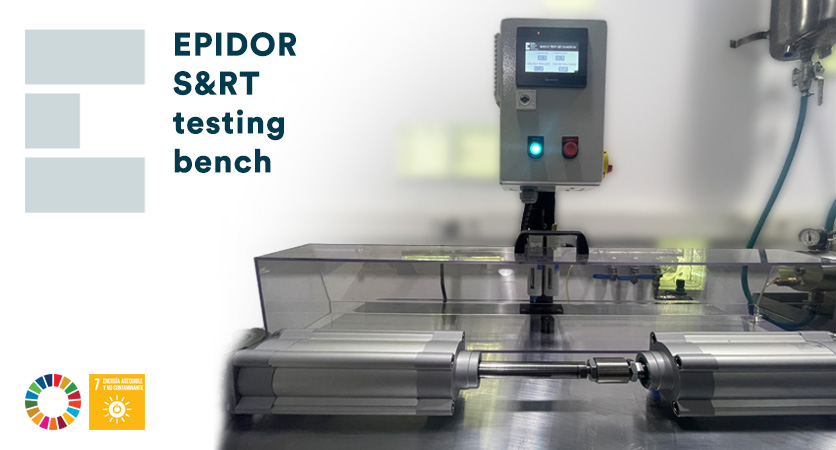

Epidor Seals and Rubber Technology testing bench

To conclude this article, some words about the Epidor Seals and Rubber Technology pneumatic test bench to carry out comparative studies.

Through our team of R&D engineers, we choose to provide access to the test bench for those customers looking to carry out real tests and draw conclusions about the performance of the part to be tested. In this way we can optimize our designs to the maximum.

Unlike other similar testing benchs, the design of two opposing cylinders reduces energy consumption and contributes to meeting one of our Sustainable Development Goals (SDGs), outlined in the 2030 Agenda.

We hope that the topics covered in this article have been of interest to you. If you would like to know more details or have any related queries, please contact our expert team in sealing solutions. We will be happy to answer all your questions.

Leave a Reply

Want to join the discussion?Feel free to contribute!