Fugitive emissions, everything you need to know

At Epidor Seals and Rubber Technology we are specialists in sealing solutions, but also focused on innovation and sustainability, which is why knowledge is necessary.

Under this premise we have carried out the webinar on fugitive emissions, with Antoine Simon, Business Manager of Epidor Seals and Rubber Technology and José Luis de Veciana Baig, area sales manager Iberia of Garlock.

If you would have liked to attend the webinar, but it was impossible, don’t worry! We leave you the link here.

Do you want to know more? We explain it here.

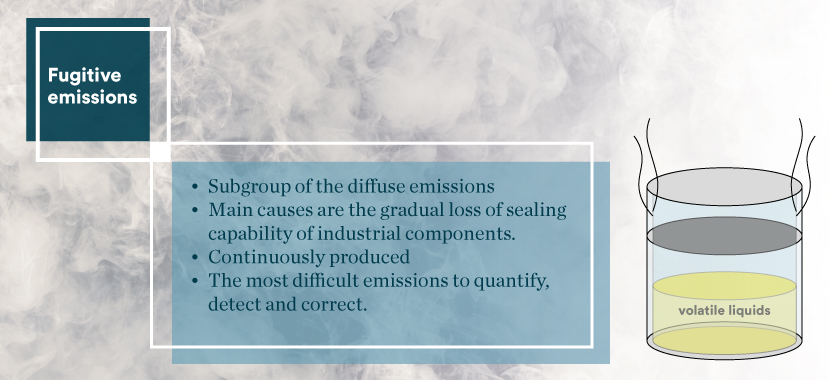

What are fugitive emissions?

Fugitive emissions are a type of non-channelled emissions. Leaks or gradual losses of product that occur through different equipment or components. These are the most difficult emissions to quantify, detect and correct.

There is no single definition of fugitive emissions, because there is no single type of fugitive emission and no single way to quantify them. This depends very much on the environment in which these emissions are found. These are mainly due to human industrial activity.

Fugitive emissions make up a total of 5% of greenhouse gas emissions, an amount that is more than significant and that has a great weight on the environment.

Legislation on fugitive emissions

It is necessary to take into account the importance in the local and European territory to have a regulation and a quantification of the emissions occurring in the industry. And thus, to be able to value and limit these emissions.

There are some regulations to consider when dealing with these emissions. Most of them have an European basis, but each country applies its own legislation, which makes the general comprehension difficult. Anyway, we can mention for example some references:

- • Regulation (EU) 2018/1999 of the European Parliament and of the Council of 11 December 2018 on the Governance of the Energy Union and Climate Action.

- • Sectorial BATs.

- • Integrated Environmental Authorisation or IEA.

Causes and factors

Fugitive emissions are unavoidable, but we must prevent them from occurring in large quantities and try to reduce them as much as possible. To do this, the most important thing is to start by knowing the causes and factors that provoke them.

Causes of fugitive emissions

Fugitive emissions can come from a variety of causes. Some of them are:

- • Wear of work equipment or its sealing elements, which causes leaks.

- • Design, construction, use or installation of the equipment.

- • An equipment error or failure, which may cause fugitive emissions.

Although it may seem like an insignificant amount, small leaks in a facility can end up becoming significant. Keep in mind that 1% of valves in gas service can generate more than 70% of the fugitive emissions in a plant.

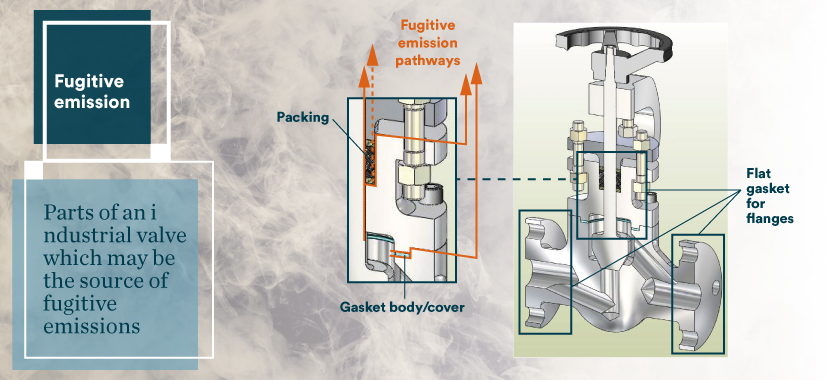

It is therefore important to take into account the parts of the valves that usually cause the most fugitive emissions, so that we can achieve good results in the short term.

Factors to be taken into account to avoid fugitive emissions

There are many factors to consider that can cause fugitive emissions to appear, increase or decrease. These are:

- • Equipment design.

- • Age and quality of equipment.

- • Installation standards.

- • Fluid vapour pressure.

- • Process pressure and temperature.

- • Number and type of sources.

- • Maintenance and inspection routines.

- • Production volume.

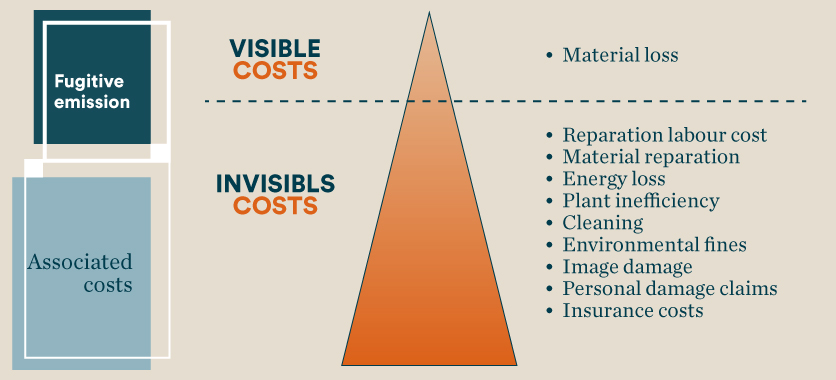

Associated costs

When we talk about the costs caused by fugitive emissions, the most worrying are those related to the impact on the environment and human health, but, in addition to these, we find the economic costs.

These are the visible costs and the invisible costs:

- • Visible costs are those related to the obvious loss of material.

- • Invisible costs relate to those costs generated indirectly by fugitive emissions. Examples are the labour required to detect and repair them, the odours and nuisance they generate with the loss of product or the cleaning costs and even fines… that they can cause.

NMVOC emissions

NMVOC emissions, i.e. emissions of Non-Methane Volatile Organic Compounds, refer to compounds that can be very toxic. Products that contribute to global warming in a significant way and damage atmospheric ozone.

These emissions are significant, since, taking 2019 as a reference year, they reached 583,000 tonnes, of which 48% came from industry.

Techniques for the prevention and reduction of fugitive emissions

Fugitive emissions are a matter of concern for the industry. Therefore, techniques have been researched and selected to avoid them. Here are some of the minimisation measures available. The use of high performance sealing systems is absolutely necessary. These are:

- • High performance flanges and gaskets.

- • High Integrity, Quality Valves and Pumps.

- • Low emissivity gaskets.

In addition, it is recommended to establish a leak detection and repair program, with, for example, valve monitoring or analysis of results.

ISO and TA-LUFT Standards

EN ISO 15848-1

Due to the problem with fugitive emissions, the ISO standard is developed to deal with these emissions in industrial valves.

EN ISO 15848-1 defines the procedures for measuring, testing and qualification of fugitive emissions in industrial valves.

TA-LUFT

This regulation, coming from Germany, deals entirely with the reduction of pollutant emissions emitted by industrial plants. The regulation, present since 1974 in Germany, has been revised and put into force in 2021 at European level.

This regulation presents a list of fluids that are dangerous for the environment or for human beings. This list is made up of 700 pages, where the limits that a fluid must have to be considered toxic or non-toxic are determined.

Thanks to the new revision made in 2021, fugitive emissions, among others, are now taken into account in this list. Giving them the importance they deserve, and TA-Luft can be considered as the Best Available Technique.

We hope this article has been of interest to you. If you have any questions about it, please contact our specialists in the field.

Leave a Reply

Want to join the discussion?Feel free to contribute!